Solving the Nightmare of Spring Assembly

- Daniel Walker

- Nov 9, 2016

- 1 min read

The Feeding of Springs in assembly operations has been an

assembly nightmare forever.

When handled in bulk, springs have a tendency to get tangled together, they intertwine and twist, interlock and basically screw into each other,

They absorb energy, so vibratory feeding can be very difficult.

Springs have been typically bowl-fed, which can cause them to become tangled, a problem

that is frequently encountered with springs that are tightly wound and contain open ends.

Problem Solved!

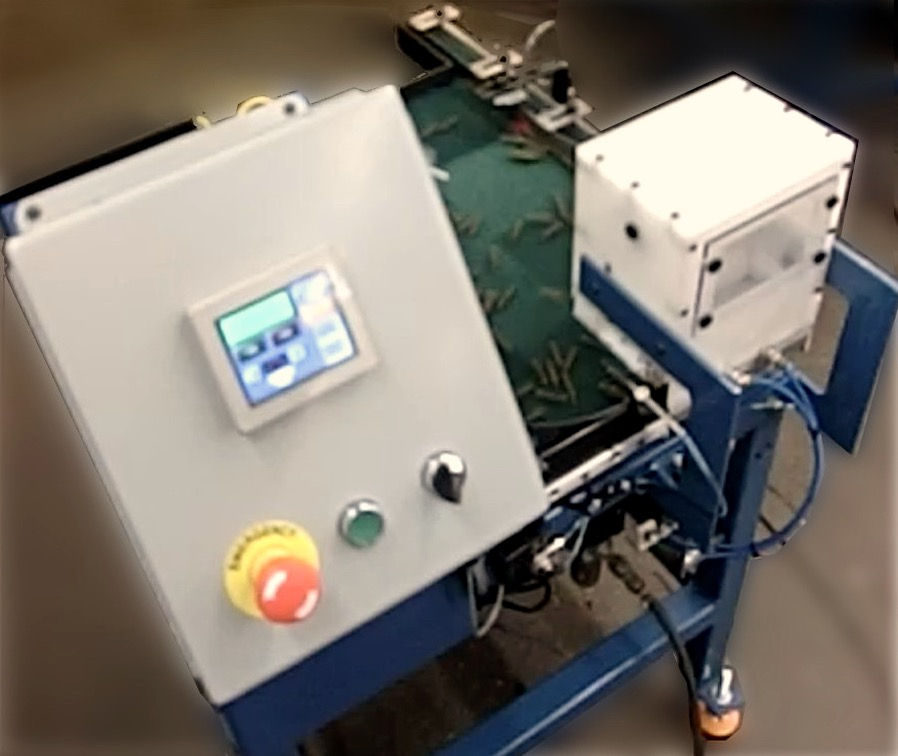

Roboshop inc. has designs and builds a system for successfully detangling springs from bulk and automatically delivering segregated springs to your next operation.

The system consists of a bulk hopper, re-circulating table with out-feed, a detangling chamber

Hi-level sensing and good/bad part recognition and spring separation.

The rejected spring recirculates back thru the detangling chamber for another opportunity to be untangled.

The most important feature of the system is Roboshop's exclusive patented feed system with plc control, a feed system that provides you with the ability to successfully feed and control the distribution of all types and sizes of springs in our vibratory feed system

For More information on Roboshop

Coil Spring Feeding Systems:

www.Roboshopinc.com

email: DanWalker@roboshopinc.com

MikeCarno@roboshopinc.com

Roboshopinc@verizon.net

Phone: 315-437-6454

コメント